Prefabricated Mass Timber Modular ADU Protoype Adaptable to the Steep Hillsides of Southern California

Our Modular Building Systems

Prefab Mass Timber Modular ADU System

|

Prefab Mass Timber Modular ADU System |

An adaptable housing system for complex terrain

The Prefab Mass Timber Modular ADU System is a research-driven building solution developed to address California’s housing crisis while reducing the environmental impact of residential construction. The system responds to the specific challenges of steep hillside sites in Southern California, combining prefabrication, mass timber construction, and circular design principles.

This system demonstrates how mass timber modular construction can outperform conventional light-frame ADUs in terms of carbon storage, construction efficiency, occupant well-being, and adaptability to difficult terrain.

What the System Solves

Lack of affordable housing in high-density urban areas.

High carbon emissions associated with conventional construction

Limited adaptability of standard ADUs to steep or irregular sites

Noise, waste, and disruption caused by on-site construction

The need for scalable, replicable housing solutions

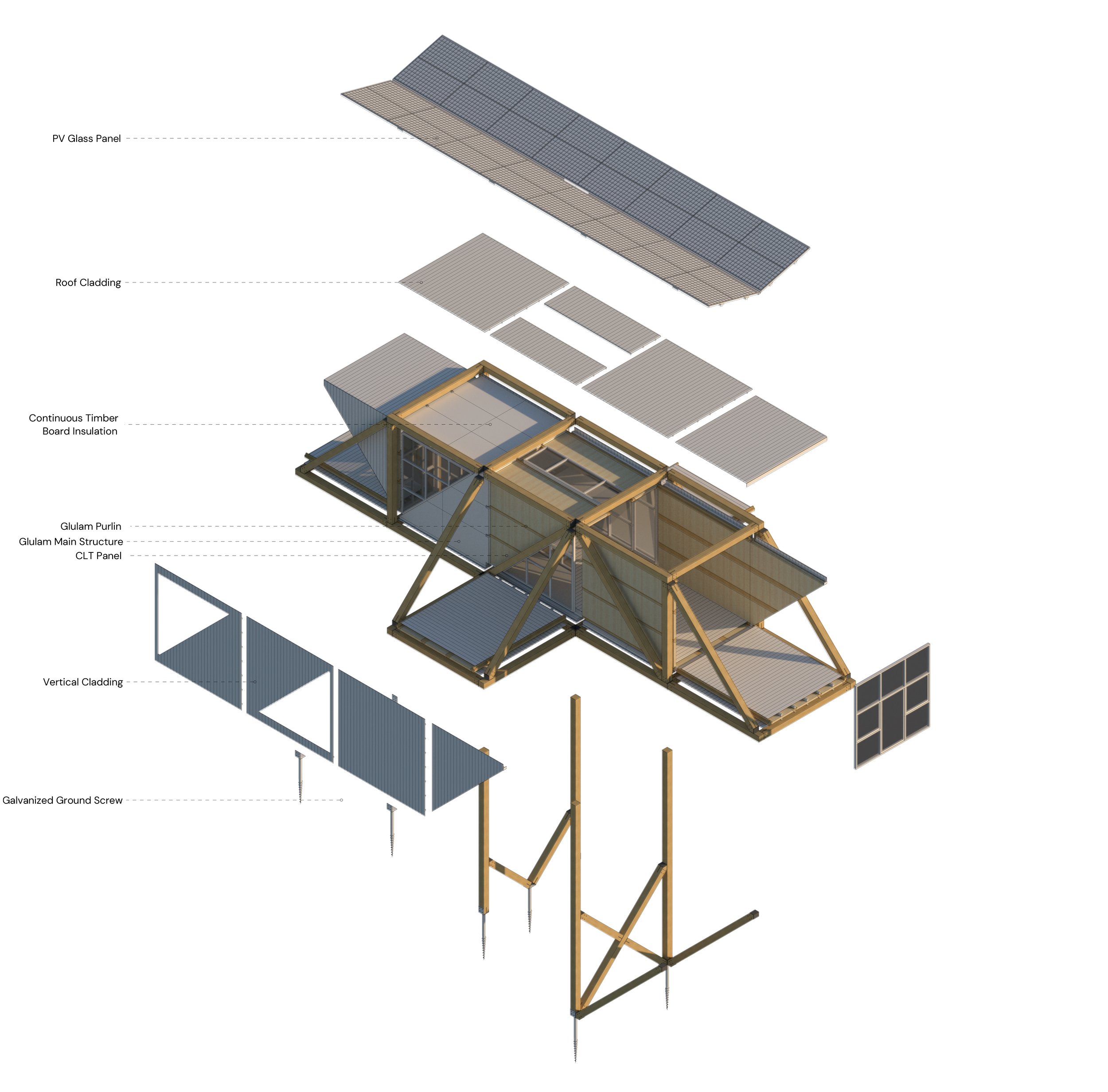

System Overview

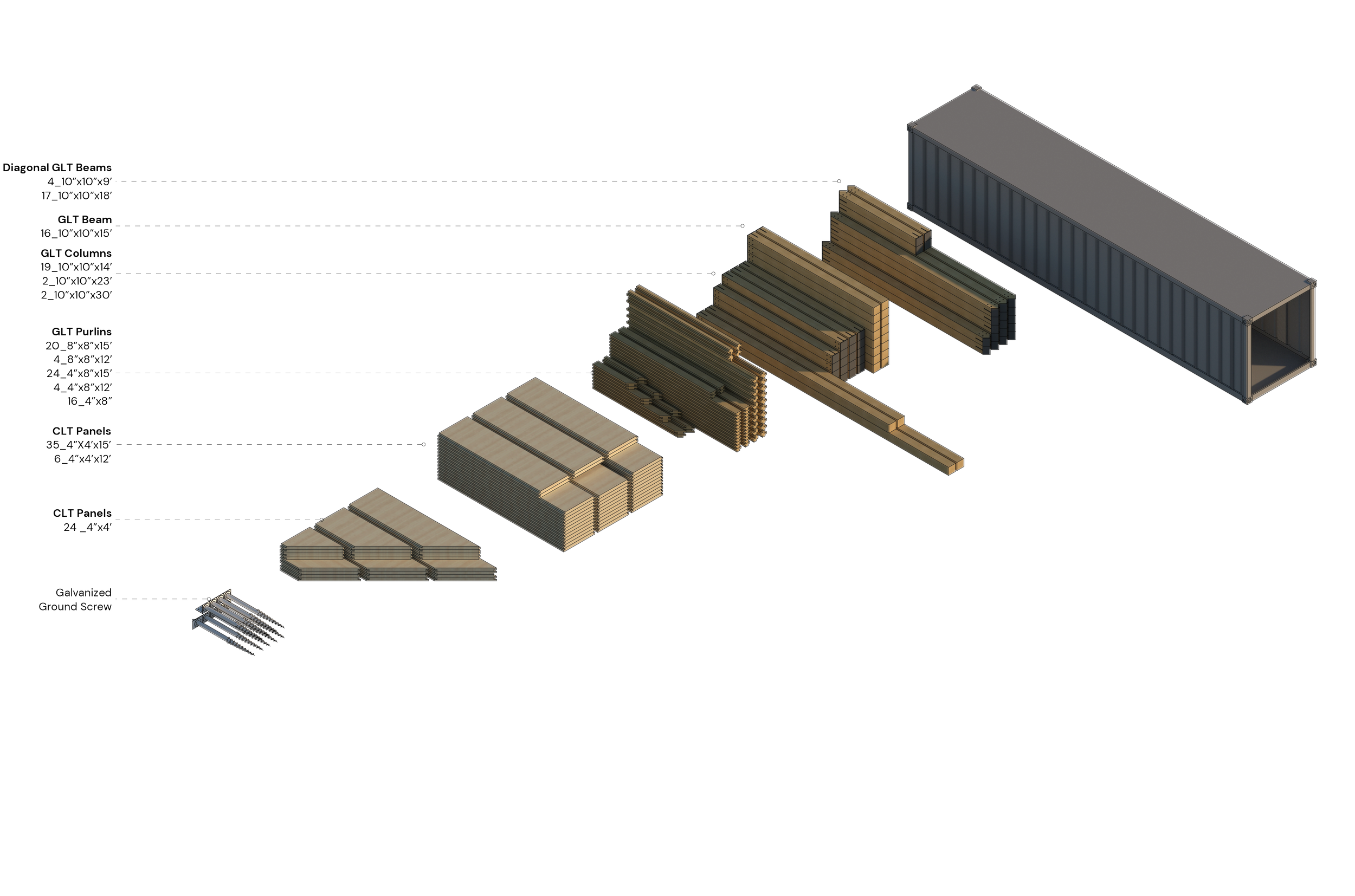

The system is based on a modular mass timber structure using CLT and glulam components, designed for off-site prefabrication and fast on-site assembly.

Its structural logic allows the unit to adapt to different slopes through an exoskeleton timber structure, minimizing the need for extensive concrete retaining walls.

Key characteristics:

Modular components designed for flexible growth and expansion

Prefabricated panels and structural elements are produced off-site

Rapid on-site installation with reduced neighborhood impact

Design optimized for Southern California climate conditions.

Environmental Performance

A comparative Life Cycle Assessment demonstrates that the mass timber ADU stores more carbon and produces fewer emissions than a conventional light-frame ADU of the same size.

Environmental benefits:

Net low-carbon or carbon-negative structural system

Reduced construction waste through prefabrication

Circular life cycle with potential for reuse, recycling, and biomass recovery

Design aligned with Design for Manufacture and Assembly (DfMA) principles

Material Strategy

The system prioritizes bio-based and natural materials, specifically mass timber sourced from sustainably managed forests.

Material advantages include:

Significant carbon storage compared to light-frame construction

Improved indoor air quality through moisture regulation

Natural acoustic dampening and thermal comfort

Reduced embodied carbon over the building life cycle

Adaptability and Scalability

The modular logic allows the system to:

Adapt to varying site slopes and orientations

Expand over time based on occupant needs

Be replicated across different sites with minimal redesign

Serve as a prototype for broader housing and infrastructure applications

This makes the system suitable not only for ADUs, but also as a foundation for future modular housing solutions.

Who This Product Is For

Private homeowners in hillside or constrained sites

Cities and municipalities addressing housing shortages

Developers exploring low-carbon housing solutions

Institutions researching scalable sustainable construction

Organizations focused on climate mitigation through the built environment

Circular by Design

Practical wisdom to the full life cycle of buildings, designing systems that can be assembled, disassembled, and adapted over time.